World of Custom Made

Creating custom jewelry involves several steps, including designing with CAD (Computer-Aided Design), casting, and finishing.

Here is an overview of the process:

Initial Consultation:

The process begins with a consultation between the jewelry designer and the client. During this meeting, the client discusses their ideas, preferences, and any specific design elements they want in the piece.

Material Selection:

Once the design is finalized, the client and designer select the materials for the jewelry, such as the type of gold, gemstones, and any other elements like enamel or wood.

3D Printing or Wax Model:

A wax model or a 3D-printed version of the jewelry is created based on the CAD design. This model serves as a prototype for the final piece. It can be inspected for fit and design accuracy.

Casting:

The wax model or 3D-printed prototype is used to create a mold. This mold is typically made from a heat-resistant material. The wax is melted out or the 3D print is burned away, leaving an empty cavity in the mold.

Casting the Metal:

The selected metal (e.g., gold) is melted and poured into the mold cavity, taking the shape of the design. This process can be done through various methods, including centrifugal casting, vacuum casting, or lost-wax casting.

Finishing:

After the metal has cooled and solidified, the rough casting is removed from the mold. This piece is known as a casting blank or casting tree, which may have multiple jewelry pieces attached to it.

The next step involves refining and finishing the piece. This includes removing any excess metal, smoothing surfaces, and adding texture or details as required.

Setting Gemstones:

If the jewelry includes gemstones, they are carefully set into their designated positions. This requires precision and skill to ensure the stones are secure and aligned properly.

Polishing and Cleaning:

The jewelry is polished to achieve a desired finish, whether it’s high shine, matte, or textured. It is then cleaned to remove any residual casting or polishing compounds.

Quality Control:

The final piece is thoroughly inspected to ensure it meets the design specifications and quality standards. Any necessary adjustments or repairs are made at this stage.

Final Presentation:

The completed custom jewelry is presented to the client for approval. If everything is as expected, the client takes possession of the unique piece.

Throughout the entire process, communication between the client and the jewelry designer is essential to ensure the final product meets the client’s vision. Custom jewelry making requires a combination of artistic design, technical skill, and attention to detail to create a one-of-a-kind piece that is both aesthetically pleasing and structurally sound.

Services

ALL WORK DONE ON PREMISES

Custom Made Jewelry

Our team specifically designs and creates according to our customer’s preferences and specifications. Offering a unique and personalized touch, allowing our customers to express their individuality and style. Custom-made jewelry includes engagement rings, wedding bands, necklaces, bracelets, earrings, and more. Our Skilled artisans and jewelers work closely with customers to understand their vision and create a one-of-a-kind piece that reflects their taste and personality. The process involves consultations, design sketches, material selection, and meticulous craftsmanship to bring the customer’s vision to life.

Remounts & Redesigns

Involves the process of transforming existing jewelry pieces into new designs or settings. This service is ideal for individuals who want to update or repurpose their jewelry while preserving sentimental value or precious gemstones.

Remounting typically involves removing gemstones from their current settings and placing them into new settings or designs. This allows for a fresh and updated look while maintaining the integrity of the original stones.

Redesign services, on the other hand, involve completely transforming the existing jewelry piece into a new design. This can include changing the overall style, adding or removing gemstones, altering the metalwork, or incorporating new elements. Both remounting and redesign services offer a cost-effective and sustainable way to breathe new life into old or outdated jewelry. It allows individuals to create unique and personalized pieces that reflect their evolving style and preferences. Skilled jewelers and designers work closely with customers to understand their vision and execute the remounting or redesign process with precision and craftsmanship.

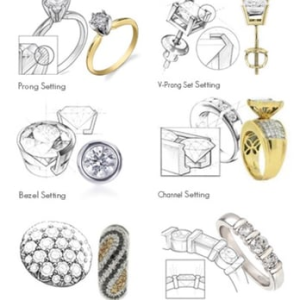

Stone Setting, Prong Rebuilds, New Heads

Stone setting involves the precise placement of gemstones into their designated settings, such as prongs, bezels, or channels. This process requires skill and expertise to ensure that the stones are securely held in place while allowing them to showcase their brilliance and beauty.

Prong rebuilds are necessary when the prongs holding a gemstone in place become worn, damaged, or weakened over time. Jewelers can rebuild or replace the prongs to ensure the stone remains securely set and protected.

New head jewelry service involves the creation and installation of a new setting, also known as a head, for a gemstone. This service is often sought when individuals want to update the style or design of their jewelry piece while keeping the original gemstone. The jeweler will create a new head that fits the specific dimensions and shape of the gemstone, ensuring a secure and aesthetically pleasing setting.

These services are essential for maintaining the integrity and beauty of jewelry pieces. Skilled jewelers use their expertise and precision to perform stone setting, prong rebuilds, and new head installations.

Ring Sizing & New Shanks

Ring resizing involves altering the size of a ring to make it larger or smaller to fit the wearer’s finger. This process typically involves cutting the ring’s shank and either adding or removing metal to achieve the desired size. Skilled jewelers use specialized tools and techniques to ensure a precise and seamless resizing, taking into consideration the design and structural integrity of the ring.

In some cases, when a ring’s shank is worn out, damaged, or needs to be replaced for aesthetic reasons, jewelers offer new shank services. This involves removing the existing shank and replacing it with a new one. The new shank can be made from the same metal as the original or a different metal, depending on the customer’s preference.

Both ring resizing and new shank services require expertise and precision to ensure the ring maintains its original design and integrity. It is recommended to consult with a professional jeweler who can assess the ring and provide guidance on the best approach for resizing or replacing the shank.

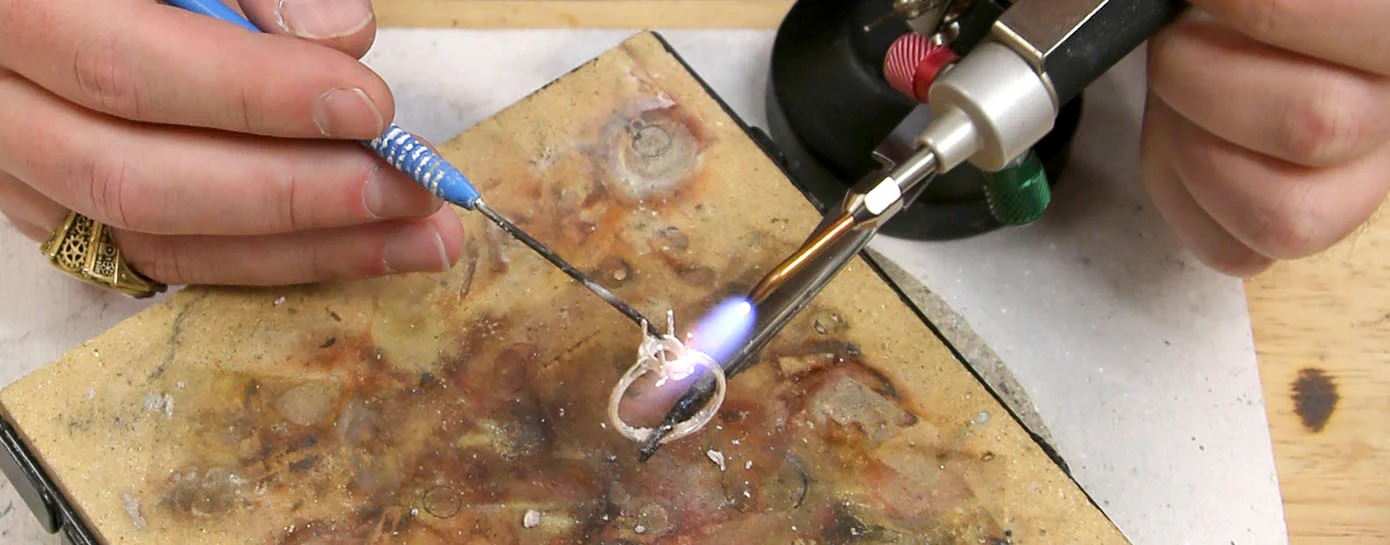

Soldering

Soldering jewelry service involves the process of joining or repairing metal components of a piece of jewelry using solder. Soldering is a technique commonly used in jewelry making to securely connect metal parts together.

During the soldering process, a skilled jeweler uses a torch to heat the metal pieces to a specific temperature. Once the metal reaches the appropriate temperature, a small amount of solder, which is a metal alloy with a lower melting point, is applied to the joint. The solder melts and flows into the gap, creating a strong bond between the metal pieces when it cools and solidifies.

Soldering can be used for various purposes in jewelry, such as resizing rings, repairing broken chains or clasps, attaching findings or settings, and adding decorative elements. It requires precision and expertise to ensure that the soldered joint is secure and aesthetically pleasing.

On Site Laser Welding

Laser welding is a precise and efficient method used in jewelry repair, resizing, and customization.

Laser welding utilizes a focused laser beam to join metal parts together. It is particularly useful for delicate or intricate jewelry pieces, as it minimizes the heat-affected zone and reduces the risk of damage to surrounding areas. The laser welding process is highly precise, allowing for seamless repairs and modifications with minimal visible marks or discoloration.

Watch Overhaul & Clean and Batteries

Rolex, Cartier, Omega, Bulova, Tissot

Comprehensive maintenance procedure performed on a timepiece to ensure its optimal performance and longevity. This service involves disassembling the watch, cleaning each component thoroughly, inspecting for any damage or wear, replacing worn-out parts if necessary, lubricating the movement, and reassembling the watch. Overall, a watch overhaul and clean service is essential for maintaining the performance, reliability, and longevity of a timepiece. It helps to prevent potential issues, extends the lifespan of the watch, and ensures it continues to function at its best.

Appraisal Services

Jewelry appraisal services involve the assessment and valuation of jewelry items to determine their worth. These services are typically conducted by professional appraisers who have expertise in evaluating various types of jewelry, including diamonds, gemstones, precious metals, and antique pieces.

The purpose of a jewelry appraisal is to provide an accurate and unbiased assessment of the item’s quality, authenticity, and value. This information is often required for insurance purposes, estate planning, resale, or simply to have a better understanding of the item’s worth.

The appraiser provides a detailed report that includes a description of the jewelry, its estimated value, and any supporting documentation or certifications. This appraisal report serves as an official document that can be used for insurance purposes or as proof of value.

Jewelry Appraisal PDF Form

Pearl Re-string

Pearl restringing service involves the process of replacing the string or thread that holds pearls together in a necklace, bracelet, or other jewelry pieces. Over time, the original string may weaken, stretch, or become worn, posing a risk of breakage and potential loss of pearls.

During the restringing process, the old string is carefully removed, and each pearl is individually inspected for any damage or imperfections. The pearls are then rethreaded onto a new, high-quality string, taking into consideration the desired length and spacing between each pearl. Knots are typically tied between each pearl to prevent them from rubbing against each other and minimize the risk of loss if the string were to break.

Professional pearl restringing ensures the longevity and security of your pearl jewelry. It is recommended to have pearls restrung every few years or if you notice any signs of wear or damage to the existing string. This service helps to maintain the beauty and integrity of your pearl jewelry, allowing you to continue enjoying them for years to come.

Laser Engraving

Laser engraving utilizes advanced laser technology to create precise and detailed engravings on various types of jewelry. This process involves using a laser beam to etch or engrave designs, patterns, text, or even images onto the surface of the jewelry piece.

Laser engraving offers several advantages over traditional engraving methods. It allows for greater precision, finer details, and the ability to engrave intricate designs that may be challenging with manual techniques. The laser beam can be controlled with high accuracy, resulting in clean and crisp engravings.

This service is commonly used to personalize jewelry items, such as rings, pendants, bracelets, and watches. It provides an opportunity to add meaningful messages, names, dates, or symbols to create a unique and sentimental piece. Laser engraving can also be used for branding purposes, adding logos or trademarks to jewelry items.

It is important to note that not all jewelry materials are suitable for laser engraving. Precious metals like gold, silver, platinum, and stainless steel are commonly compatible, while softer materials like pearls or certain gemstones may not be suitable.

Jewlery Polishing and Restoration

Jewelry polishing service involves the process of restoring the shine and luster of jewelry pieces. Over time, jewelry can become dull, scratched, or tarnished due to regular wear and exposure to various elements. Jewelry polishing helps to remove surface imperfections, scratches, and tarnish, bringing back the original brilliance and shine of the piece. During the polishing process, our skilled jewelers use specialized tools and techniques to gently buff the surface of the jewelry, removing any scratches or blemishes. They may also use polishing compounds or solutions to further enhance the shine and remove tarnish. The specific method used will depend on the type of metal and gemstones involved, as different materials require different approaches to avoid damage. Jewelry polishing not only improves the appearance of the piece but also helps to maintain its longevity and value. It is recommended to have jewelry professionally polished periodically to keep it looking its best.